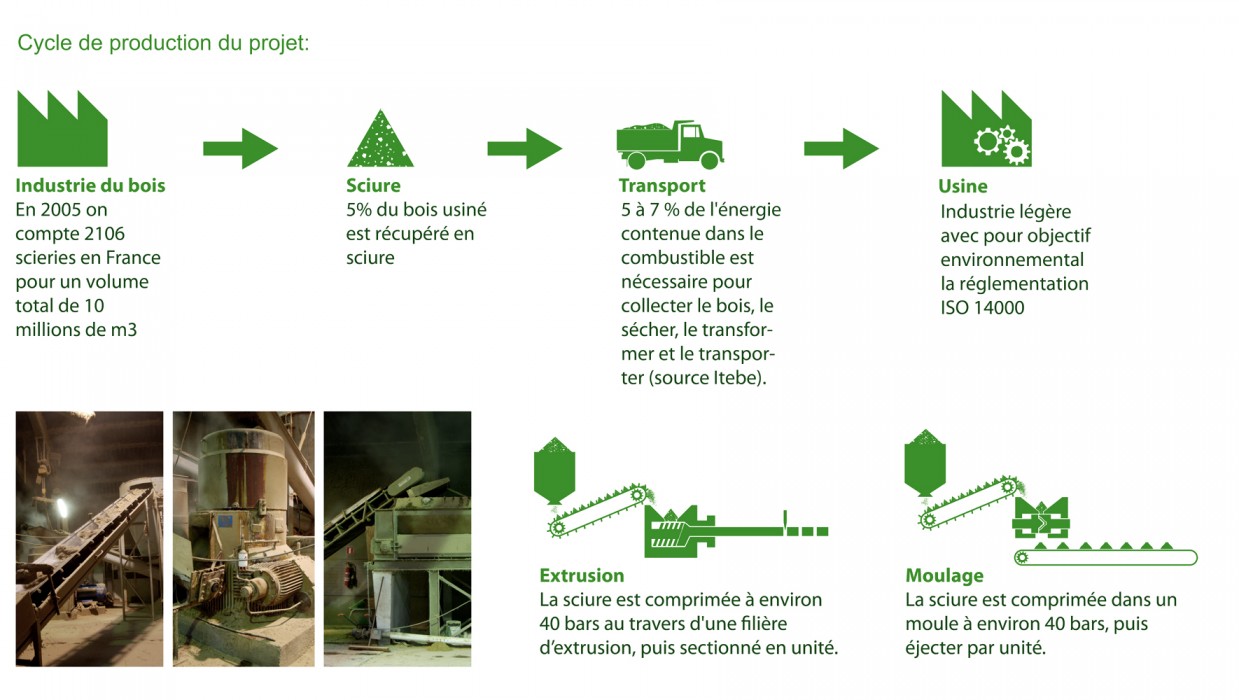

Compressed wood belongs to a perfect cycle. It is made of residues of industry waste. Industrially shaping is easy and without chemical additive. It is a material 100% natural and biodegradable, more compact than sawn timber, it offers caloric qualities 3 to 4 times superior. Heating with wood is in progression, and pushed by labels like Green Flame, delivered by ADEME. It is a question of integrating this material in daily practices and uses to develop it.

It is a question of integrating this material in daily practices and uses to develop it. The first stage is to work on its first use: the universe of fire, from its imaginary to its contemplation. It is the project “Faire un Feu”, realized in three steps. The second intervention is a technological transfer to other uses: it is the project “Etude”.

“Amorce” is a natural firelighter in opposition to chemical firelighters. It is set on a stack of paper. Its shape accelerates the combustion of the whole set by air drainage. The object of 25 cm diameter is hollow and stackable; it is molded in a cons-form shape by compression.

“Fagot” is a sectionable extruded log that takes the image of a wood faggot in its shape. Its shape allows breaking one or several twigs depending on the fire requirements. Its crenellated form makes it possible piling it up it easily.

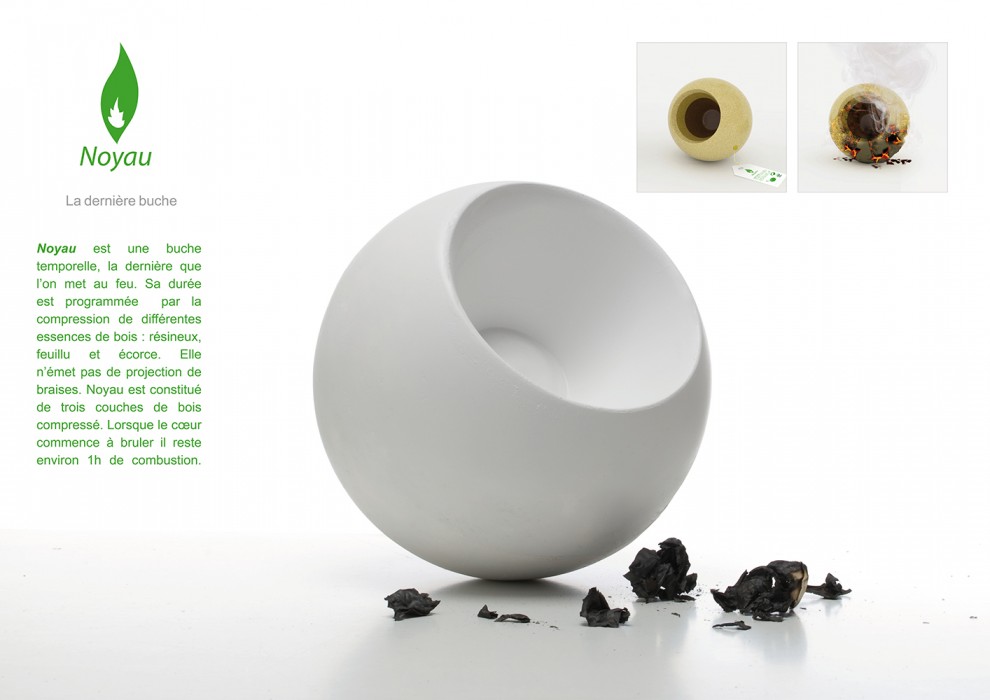

“Noyau” is a temporal log, the last one that you put in the fire. Its duration is programmed by the compression of various wood species: coniferous, leafy and barks. It does not emit any projection of ember. “Noyau” consists of three compressed wood layers. When the heart starts to burn, remains approximately 1h of combustion.

« Absorption »

Smell and liquid absorption faculties of compressed wood allow imagining an air purifier for refrigerator. Its wings provide a large contact surface with air and adapts to the refrigerator grids. When it is saturated, it is thrown in compost or with organic waste.

« Decomposition »

Compressed wood disaggregates in contact with water. We propose a nail to plant seeds. The sawdust charged with seed and natural fertilizers is then molded. The size of nails defines the depth where the grains should be planted. Into ground it breaks up, releases the fertilizers and the seeds.

« Protection »

Sawdust can be compressed around an object in a way to hold it firmly. In the field of packaging it could be an alternative to synthetic foams.